The pratix comes with a handheld console at the machine that downloads programs from your office PC. If you need to resurface the spoilboard on the fly, all your programs have to redone at the office and then downloaded again to the console to account for the new BZ offset value. This takes time because our programs coming from CV are in xxl format, and you use the win-xiso converter to get. So it can take 5-15 minutes of programming time until you are running again after a spoilboard skim. There is no way round this that I know of. You could perhaps pre-plan the SB skims every 15-20 sheets, and then prepare the iso files in separate folders ready to be downloaded. But if you need to change a tool on the fly, then all your.

iso files are useless again, because the tool length and other tool info is embedded in the. If there is an issue mid-cycle and you have to stop the program (e.g. someone accidentally touches the safety bumper), you have no option (that I am aware of) to restart the program from the point you stopped at, you must redrill and reroute everything from the beginning. I surmise that if the best SCM operator in the world would race the average Joe on a Weeke, the Weeke would do the same 10 kitchens in half the time (perhaps a little exaggerated). I know I am being hard on SCM here, and I am a self admitted perfectionist, but casual remarks by a Weeke user about how quick and easy their interface is, simply do not sink into people's brains unless you have felt on your flesh what it's like not to have those features and functions Weeke/Homag users take for granted.Īgain, I do not sell Weeke/Homag.

This was exactly the response I was trying to elicit! If I am missing something here, SCM users please speak up and help out! Thanks!ġ1/16/15 #10: Sketchup to Xilog Maestro.

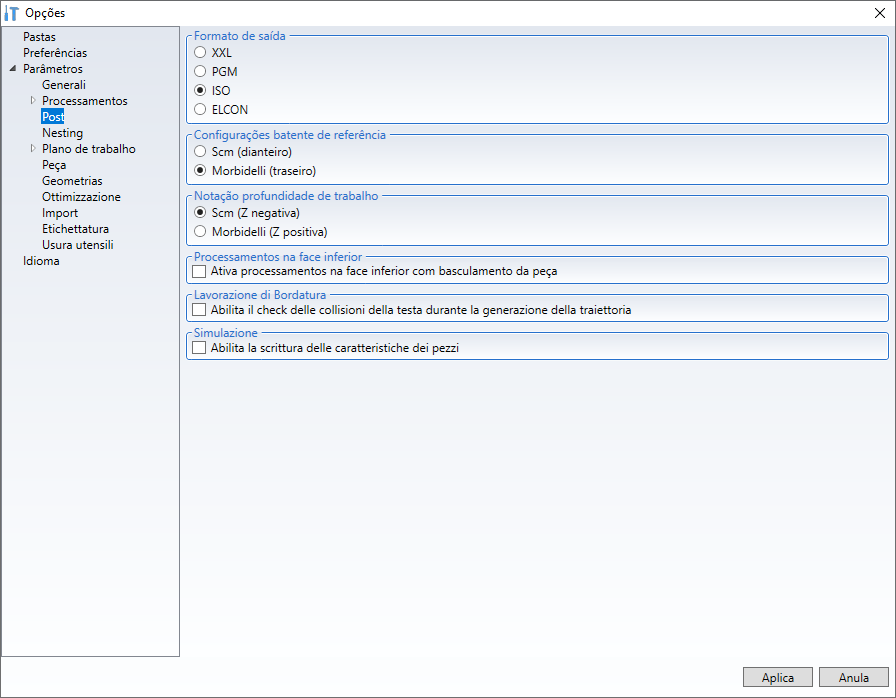

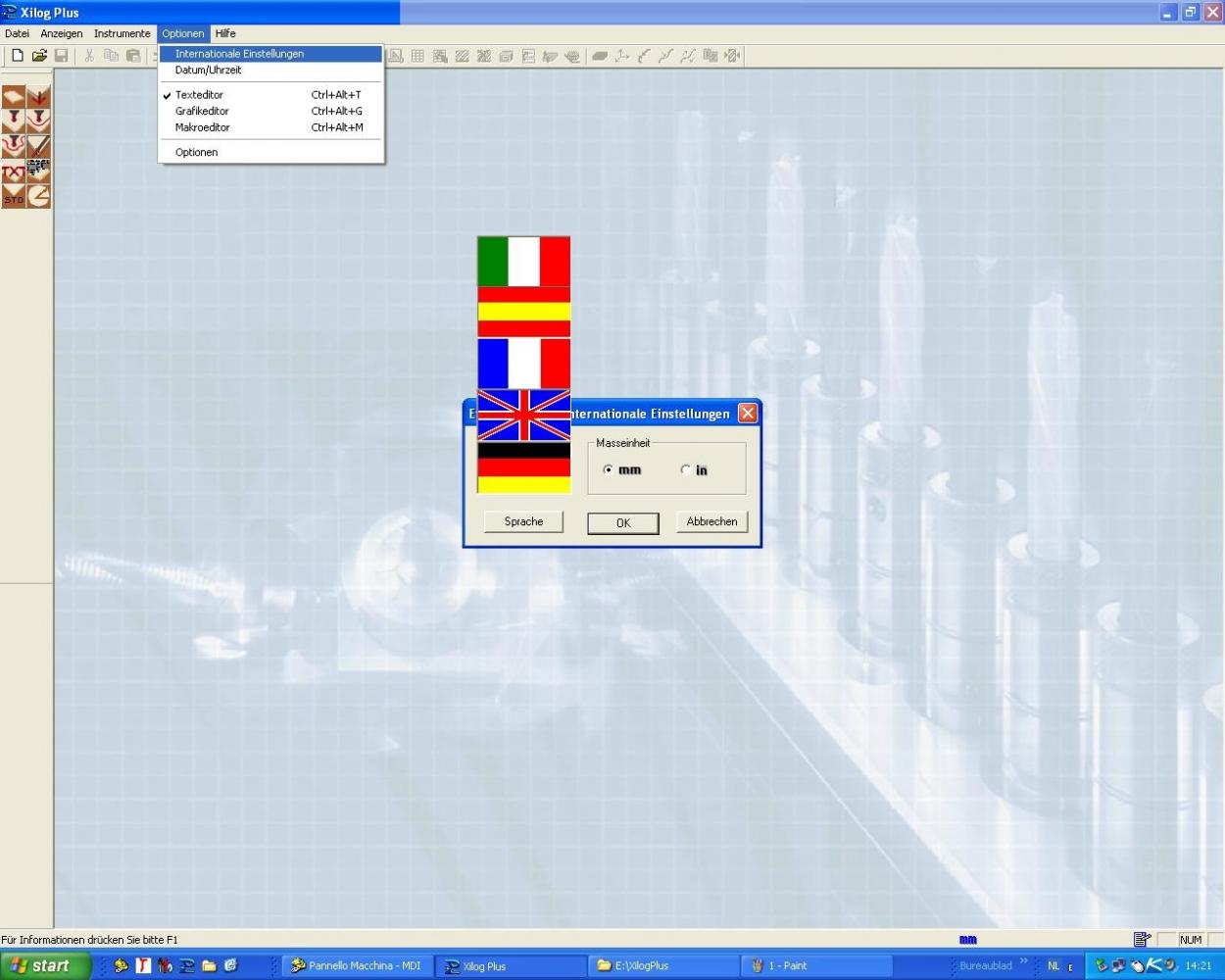

My problem has been bad or non existent training from the get go.īy "the synax varying from machine to machine" I mean Z positive/negative, zero at front or rear of machine, xxl, pgm, or iso controls are machine specific. (Cyflex also has different code for borings I believe). I am no programmer, I am a simple CNC user, but I can tell you that good software companies such as Mozaik and Polyboard could not even get my machine to work, and Enroute and Cabinet Vision fumbled around a good deal before they got it right.

0 kommentar(er)

0 kommentar(er)